The project will involve investigating a novel seaweed-ensiling process as an alternative to drying to preserve seaweeds nutritional and monetary value. The study will also investigate the waste effluent produced by the silage. Seaweed cultivation optimisation strategies will be studied with the aim of maximising seaweed protein and/or mannitol content.

Update September 2020

AgRefine is a Disruptive Innovative Cooperative Entrepreneurial (DICE) education, training and skills development programme rolling out the next generation of Agri Biorefinery and Valorisation Bioeconomy leaders. This project consists of 15 highly interdisciplinary and inter-sectoral PhD projects, each specialising in specific aspects of the bioeconomy.

AgRefine, a European Training Network (ETN), will train 15 Early Stage Researchers (ESRs) in the necessary skills and knowledge to position Europe as the global leader in developing an agri-bioeconomy industry based on the advanced biorefinery technologies.

Aim:

Its overall aim is to address the shortcomings and overcome the weaknesses that current stand-alone AD and biorefinery technologies possess.

BMRS Role:

BMRS will host ESR 7 (Priya Pollard) who will investigate a novel seaweed-ensiling process as an alternative to drying to preserve seaweeds nutritional and monetary value. The study will also investigate the waste effluent produced by the silage. Seaweed cultivation optimisation strategies will be studied with the aim of maximising seaweed protein and/or mannitol content.

BMRS will also provide ESR’s 3 (Eleftheria Papadopoulou), 5 & 8 (Mariana Cerca) with industry experience over their secondments.

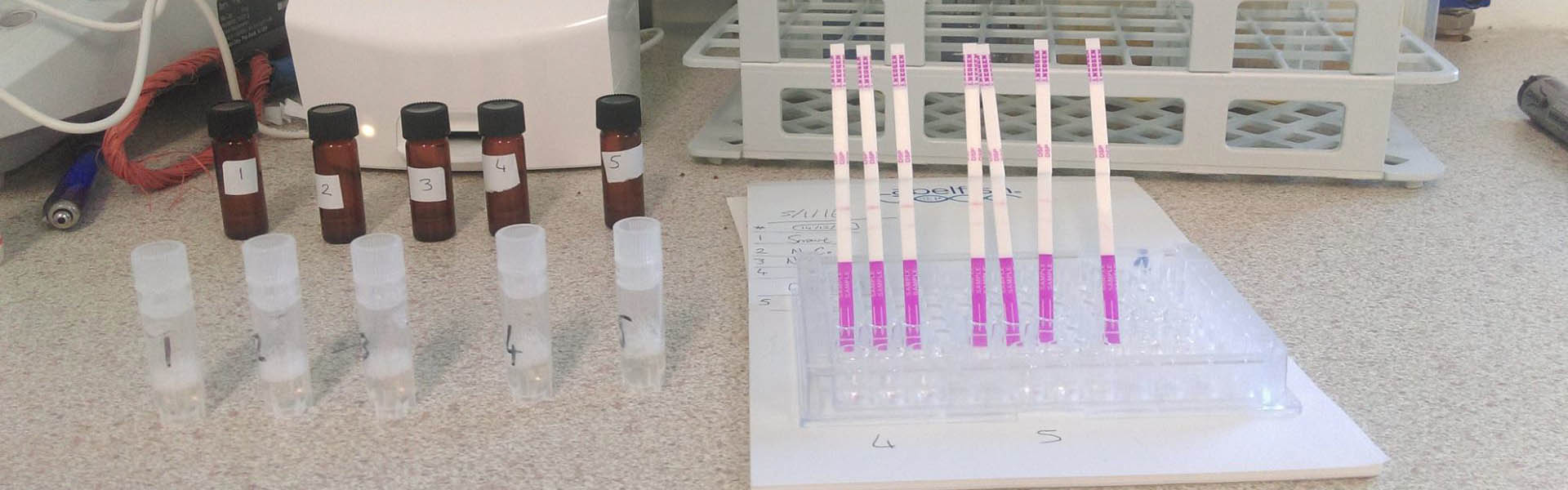

Seaweed being prepped for ensilage

Seaweed being prepped for ensilage Seaweed being compacted into buckets for ensilage.

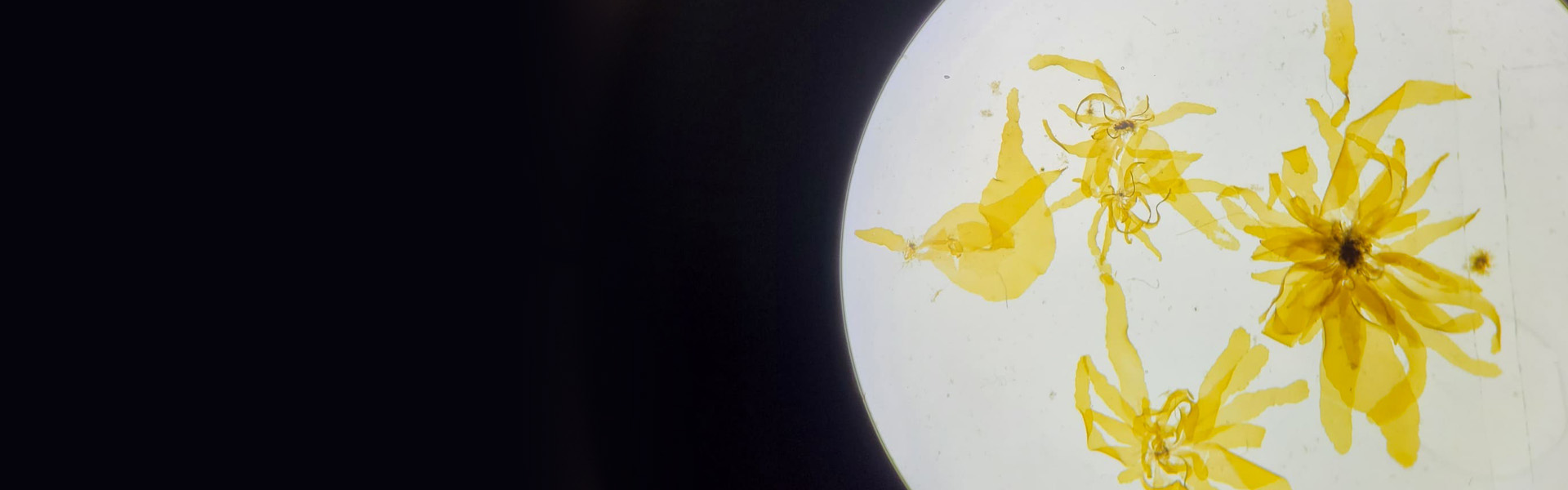

Seaweed being compacted into buckets for ensilage. Collection tubes labelled and ready for leachate collection

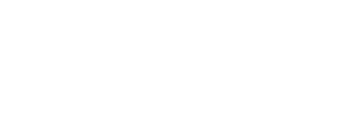

Collection tubes labelled and ready for leachate collection pH of Leachates being monitored on day 21 of ensilage.

pH of Leachates being monitored on day 21 of ensilage. Leachate collected and stored for further analysis.

Leachate collected and stored for further analysis. Leachates collected from buckets on day 90 of ensilage.

Leachates collected from buckets on day 90 of ensilage. Bucket Day 90 of ensilage.

Bucket Day 90 of ensilage. Bags day 90 of ensilage

Bags day 90 of ensilage Ensiled seaweed and leachate being shipped off to the Technical University of Denmark (DTU) for down-stream processing.

Ensiled seaweed and leachate being shipped off to the Technical University of Denmark (DTU) for down-stream processing. Spraying collectors with Alaria esculenta gametophytes.

Spraying collectors with Alaria esculenta gametophytes.

Small scale silage optimization tests have begun on select kelp species.

Homogenising kelp with additives before ensilage.

Homogenising kelp with additives before ensilage. Kelp in vacuum sealed bag on day zero of ensilage.

Kelp in vacuum sealed bag on day zero of ensilage.